How to Choose the Best Submersible Dirty Water Pump for Your Needs

When it comes to managing water removal in construction sites, basements, or flood-prone areas, selecting the right submersible dirty water pump can significantly impact efficiency and effectiveness. According to a recent industry report by the Pump Manufacturers Association, the demand for submersible dirty water pumps has increased by over 15% in the last two years due to rising environmental challenges and the need for reliable water management solutions. This surge highlights the importance of making informed choices when selecting a pump, as the right model can transform labor-intensive tasks into streamlined processes.

Expert opinions reinforce the necessity of understanding one’s specific requirements. John Smith, a renowned water management consultant, notes, “Choosing the appropriate submersible dirty water pump is not just about capacity; it’s about matching the pump’s specifications to the unique demands of the environment it will operate in.” His emphasis on tailored selection underscores the critical factors every buyer should consider, from pump capacity to the type of debris handled. As we delve into the various features and functions of submersible dirty water pumps, it becomes clear that a well-informed decision can lead to improved performance, reduced downtime, and enhanced longevity of the equipment.

Understanding Submersible Dirty Water Pumps: An Overview

Submersible dirty water pumps are essential tools designed to handle challenging fluid management tasks. Understanding their functionality is crucial for determining the right model for specific applications. These pumps operate underwater, allowing them to efficiently move dirty water that may contain solids and debris. Their construction typically includes a sealed motor and an impeller designed to withstand the harsh conditions of contaminated environments.

When considering a submersible dirty water pump, it's important to evaluate key features such as capacity, power, and maximum head height. Capacity refers to how much water the pump can move over a specific time, while power indicates the strength of the motor, affecting the pump's ability to handle larger quantities of water or more significant solids. Additionally, the maximum head height serves to determine how high the pump can lift water, which is vital for applications where the discharge point is above the water source. By grasping these fundamental aspects, users can make informed decisions tailored to their specific needs.

Key Features to Consider When Selecting a Dirty Water Pump

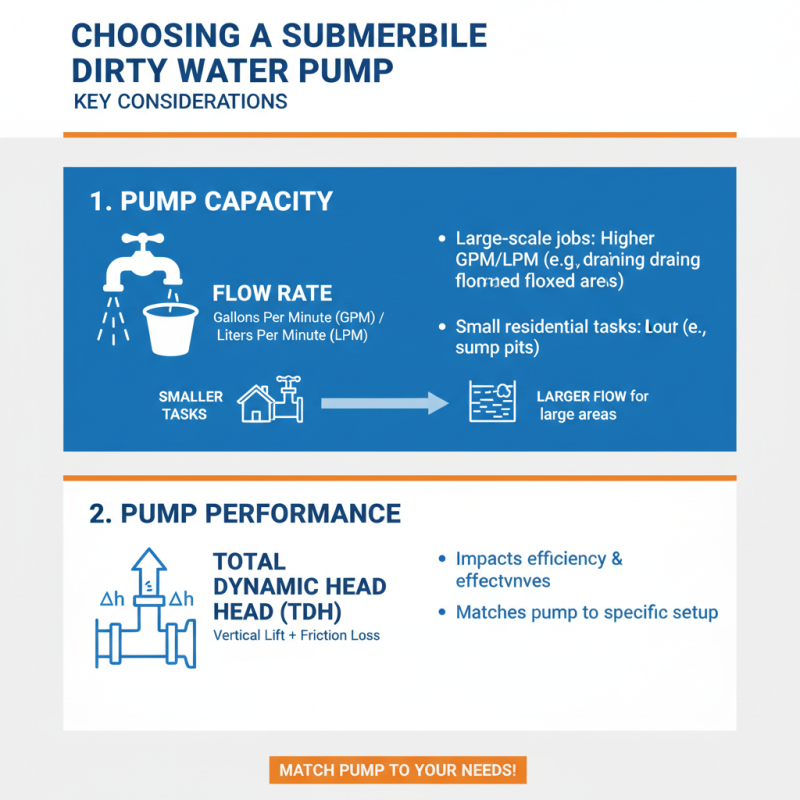

When selecting a submersible dirty water pump, understanding the key features is essential to ensure it meets your specific needs. One of the primary factors to consider is the pump's capacity, which includes both the flow rate and the total head height. The flow rate determines how quickly water can be pumped out, measured in gallons per minute (GPM), while the total head height indicates how high the water can be lifted. For outdoor use, especially in flooded areas or construction sites, a higher capacity pump may be necessary to handle larger volumes of water.

Another critical feature to evaluate is the pump's construction materials and design. Submersible dirty water pumps are often exposed to various debris and contaminants, so choosing a model made from durable materials like stainless steel or tough plastic will enhance longevity. Additionally, the design of the impeller plays a significant role in its efficiency. Look for pumps with semi-open or vortex impellers that can handle solids without clogging. Lastly, consider the ease of maintenance—features like removable filters and simple disassembly can save time and effort in the long run, ensuring the pump remains in optimal working condition.

Assessing Pump Capacity and Performance for Your Needs

When choosing a submersible dirty water pump, assessing pump capacity and performance is crucial to ensuring that the pump meets your specific needs. Start by determining the maximum flow rate required for your application—this is typically measured in gallons per minute (GPM) or liters per minute (LPM). A higher flow rate is essential for large-scale jobs, such as draining flooded areas, whereas a lower rate may suffice for smaller residential tasks. Additionally, consider the total dynamic head (TDH), which combines the vertical lift and any friction losses in the pipes. This measurement will impact the efficiency and effectiveness of the pump in your particular setup.

Tips: Before making a purchase, always check the pump's specifications against your project's demands. Drill down into details like motor power, impeller design, and the type of materials used in construction, as these factors significantly affect performance and durability. Also, ensure that your chosen pump can handle the solids and debris typically found in the water you'll be pumping.

Pay attention to energy efficiency as well. Opting for a pump with a lower energy consumption rating can help you save on operational costs over time. Look for features like automatic float switches for more convenient operation, especially if you expect to run the pump for extended periods. An energy-efficient and properly sized pump will not only perform better but also prolong equipment lifespan and reduce the risk of unexpected failures.

Evaluating Build Quality and Materials of Submersible Pumps

When selecting a submersible dirty water pump, assessing the build quality and materials is critical to ensure longevity and reliability. Pumps made from high-quality materials like stainless steel or heavy-duty thermoplastics tend to offer better resistance to corrosion and wear, especially in harsh environments. Opting for a pump with a robust housing reduces the risk of damage during heavy use, which is especially important for projects involving muddy or debris-laden water.

Tips: Always check for features such as a protected impeller and anti-clogging mechanisms. These features not only enhance performance but also prolong the pump's life. Additionally, look for models with thermally protected motors to prevent overheating during extended operation.

Another important aspect to consider is the pump's seal and waterproofing. A well-sealed pump prevents water ingress, protecting the motor and components from damage. Look for pumps that utilize double seals for added protection, particularly in environments where submersion is prolonged. Choosing a pump with these considerations will significantly improve your pumping experience and efficiency.

Tips for Maintenance and Longevity of Your Dirty Water Pump

When it comes to maintaining and ensuring the longevity of your dirty water pump, regular upkeep is crucial. According to the Pump Industry's annual report, over 30% of pump failures are attributed to inadequate maintenance. To avoid this, start with routine inspections. Check for debris and blockages that can impede the pump’s function. Regularly clean the inlet strainer and inspect the impeller for wear. This simple action can significantly extend the lifespan of your pump, which averages around five years depending on the make and model, but proper care can add several additional years.

Another important factor is monitoring the pump's operating environment. As noted in the Fluid Machinery Division's research, pumps operating in debris-heavy or abrasive environments can face accelerated wear. To mitigate this, consider using a filter as part of your pump setup. Additionally, ensure that the pump is not running dry, as this can lead to catastrophic failure. Keeping your pump in proper working conditions by adhering to these maintenance tips can ensure efficient operation and a longer service life, ultimately saving you time and money in repairs or replacements.

Related Posts

-

Transform Your Garden: The Ultimate Guide to Submersible Water Pumps for Efficient Irrigation

-

Exploring Market Trends for Submersible Dirty Water Pumps at the 138th China Import and Export Fair 2025

-

The Essential Guide to Choosing the Right Submersible Pump for Your Needs

-

Choosing the Right Submersible Pump: Key Specs and Insights to Boost Your Efficiency

-

How to Choose the Right Submersible Pump for Your Needs: A Complete Guide

-

Exploring Water Pump Innovations for Home Use at the 2025 China Import and Export Fair