How to Choose the Right Submersible Pump for Your Needs: A Complete Guide

Choosing the right submersible pump can seem like a daunting task, especially with the myriad of options available on the market today. "Selecting the appropriate pump not only enhances efficiency but also ensures longevity and reliability in operation," notes John Smith, a leading expert in the submersible pump industry with over 20 years of experience. As such, understanding your specific needs and the functionalities of various submersible pumps becomes essential.

Submersible pumps are designed to operate while submerged in the fluid they are pumping, making them an ideal choice for applications ranging from residential drainage to industrial wastewater management. With a proper selection process, one can maximize the pump's performance, energy efficiency, and overall cost-effectiveness. This guide aims to simplify that process by providing a comprehensive overview of key considerations—such as pump size, power source, and the type of fluid being pumped—ensuring that you make an informed decision tailored to your unique requirements.

Understanding the Different Types of Submersible Pumps and Their Applications

When selecting the right submersible pump for your needs, it’s crucial to understand the different types available in the market and their specific applications. The primary categories include borewell submersible pumps, which are designed for deep well applications, and dewatering pumps, suitable for removing unwanted water from construction sites or flooded areas. Additionally, there are sewage submersible pumps effectively used in wastewater management systems. Each type has unique features and benefits tailored for particular tasks, ensuring optimal performance based on the task at hand.

Tips: Consider the flow rate and head height specifications when choosing a pump to ensure it meets your operational requirements. Furthermore, assess the material durability to match the pumping environment, especially if handling abrasive materials like slurry or wastewater. Regular maintenance is essential; create a schedule for inspections and maintenance to prolong the lifespan of the pump and maintain efficiency in operations.

Moreover, advancements in solar and geothermal technologies are expanding the applications for submersible pumps in sustainable energy practices. As industries evolve, the need for reliable and efficient pumps will continue to grow, emphasizing the importance of making informed choices in pump selection to optimize performance and sustainability.

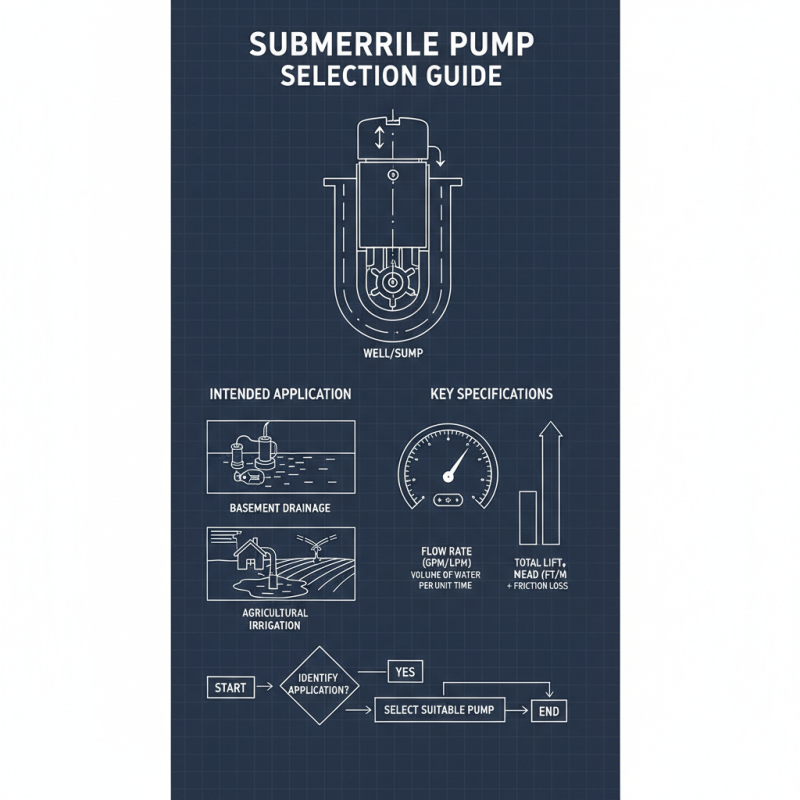

Key Factors to Consider When Choosing a Submersible Pump

When selecting the right submersible pump, several key factors come into play that can significantly impact your decision. First and foremost, consider the pump's intended application. Different tasks, such as draining a flooded basement or irrigating farmland, require pumps with specific capabilities. Understanding the required flow rate and total dynamic head is essential; these specifications dictate how efficiently the pump will perform in your given circumstances.

Another critical aspect to evaluate is the pump's material construction, especially if it will be exposed to abrasive or corrosive substances. Pumps made from stainless steel or thermoplastic are more durable and resistant to wear under harsh conditions. Additionally, pay attention to the power source of the pump, as options range from electrically powered to gasoline-driven models. The power supply can affect your operational flexibility and efficiency. Keep these factors in mind to ensure you select a submersible pump that meets your precise needs and offers lasting performance.

Evaluating Pump Performance Metrics: Flow Rate, Head, and Efficiency

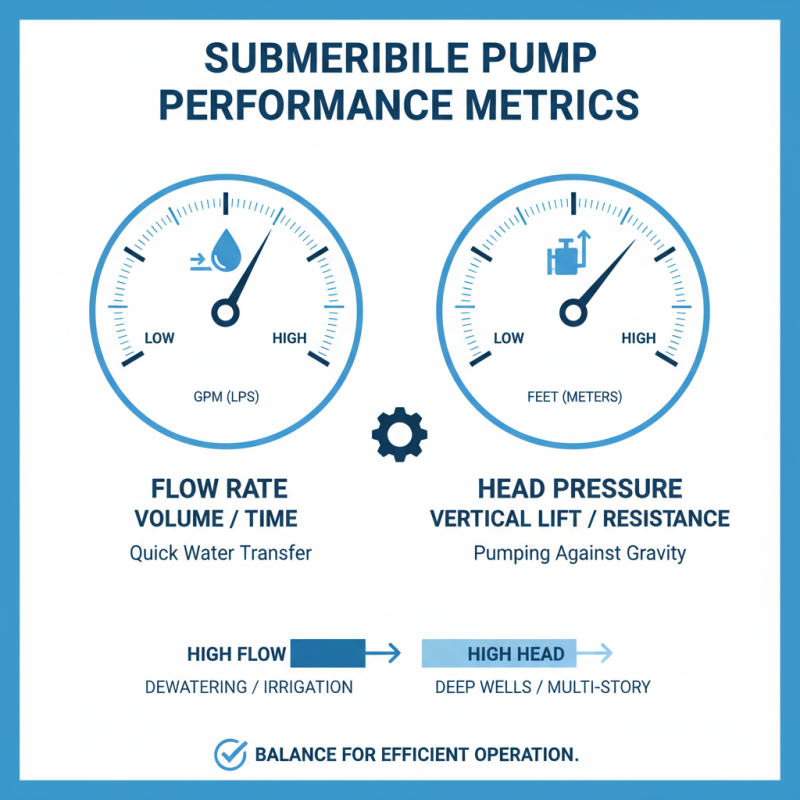

When selecting a submersible pump, understanding its performance metrics is crucial. The flow rate, measured in gallons per minute (GPM) or liters per second (LPS), indicates how much water the pump can move at a given time. A higher flow rate is beneficial for applications requiring quick water removal or transfer, such as dewatering or irrigation. However, it’s essential to balance flow rate with head pressure, as a pump's effectiveness in pushing water vertically or through resistance is critical in real-world scenarios.

Head refers to the maximum height the pump can lift water, expressed in feet or meters. This metric is essential if the installation involves moving water from deep wells or basements. Additionally, efficiency is another important factor to consider; it reflects how much energy the pump consumes in relation to the water it moves. Choosing a pump with higher efficiency can lead to long-term cost savings and reduced environmental impact. By carefully evaluating these performance metrics, you can ensure that the submersible pump you select meets your specific requirements effectively and economically.

Material Selection for Durability and Compatibility in Submersible Pumps

When selecting a submersible pump, one of the most critical factors to consider is the material from which it is constructed. Choosing the right materials not only ensures durability but also guarantees compatibility with the fluids being pumped. According to a report by Grand View Research, the global submersible pump market is projected to reach USD 23.6 billion by 2025, emphasizing the need for high-quality materials that can withstand various harsh environments.

For example, stainless steel pumps are renowned for their resistance to corrosion and rust, making them ideal for applications in seawater or other corrosive environments. In contrast, thermoplastic pumps are lightweight and provide excellent chemical resistance, making them suitable for transporting aggressive chemicals. A study published by the American Society of Mechanical Engineers (ASME) indicates that using the appropriate material can extend the lifespan of a pump by 30%, reducing maintenance costs and downtime significantly. Therefore, understanding the specific requirements of your application is crucial for achieving optimal performance and reliability in submersible pumps.

Cost Analysis: Budgeting for Your Submersible Pump Investment

When budgeting for a submersible pump, understanding the total cost of ownership is crucial. Initially, the purchase price of the pump will vary significantly based on its size, capacity, and features. Basic models may start around a few hundred dollars, while high-capacity pumps designed for industrial use can easily run into the thousands. It's essential to balance your requirements with available options, as a higher initial investment might result in lower long-term operational costs.

In addition to the purchase price, consider the installation and maintenance costs. Installing a submersible pump often requires professional assistance, which can add to your overall budget. Regular maintenance is also necessary to ensure efficiency and longevity, which may include periodic inspections, cleaning, and potential repairs. Setting aside a portion of your budget for these ongoing costs can prevent unexpected financial strain and ensure your pump operates effectively throughout its lifespan.

Related Posts

-

Exploring Market Trends for Submersible Dirty Water Pumps at the 138th China Import and Export Fair 2025

-

Transform Your Garden: The Ultimate Guide to Submersible Water Pumps for Efficient Irrigation

-

Choosing the Right Submersible Pump: Key Specs and Insights to Boost Your Efficiency

-

The Essential Guide to Choosing the Right Submersible Pump for Your Needs

-

2025 Top 10 Submersible Dirty Water Pumps for Effective Waste Management

-

What is a Small Pump and How Does It Work in Various Applications