Choosing the Right Submersible Pump: Key Specs and Insights to Boost Your Efficiency

In today's industrial landscape, the choice of a submersible pump plays a crucial role in ensuring operational efficiency and cost-effectiveness across various applications. Reports indicate that the global submersible pump market is projected to reach $19.6 billion by 2027, driven by rising demand in sectors such as water and wastewater management, agriculture, and mining (Grand View Research, 2021).

Selecting the right submersible pump not only maximizes energy efficiency but also minimizes maintenance costs, which can significantly impact overall productivity. Key specifications such as flow rate, energy consumption, and the nature of the fluids being handled are essential considerations that directly influence performance. By understanding these factors and leveraging industry insights, businesses can enhance their operational initiatives and ensure sustainable practices in their pumping systems, ultimately leading to improved water management solutions and reduced environmental impact.

Understanding Flow Rate: Essential Metrics for Selecting Submersible Pumps

When selecting a submersible pump, understanding the flow rate is crucial in ensuring optimal performance and efficiency. Flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), indicates the volume of fluid the pump can move within a specific time period. This metric helps you determine whether a pump can meet the demands of your project, whether it's draining a flooded area, supplying water for irrigation, or facilitating wastewater management.

Moreover, it's essential to consider how the flow rate interacts with other parameters such as total dynamic head (TDH) and pump size. A pump's efficiency can significantly decrease if it's operating outside its designed flow rate range. Therefore, it's important to assess the needs of your application before making a final choice.

Factors such as the height to which water must be lifted and the distance it needs to travel can also impact flow rate performance. By thoroughly evaluating these essential metrics, you can select a submersible pump that not only meets your needs but also enhances your overall operational efficiency.

Evaluating Head Pressure: Key Factors for Pump Performance and Efficiency

When evaluating submersible pumps, understanding head pressure is crucial for optimizing performance and efficiency. Head pressure, defined as the height that the pump can raise water, directly influences the pump's ability to perform under varying conditions. According to a recent report by the Hydraulic Institute, selecting a pump with the correct head pressure can improve efficiency by up to 20%, highlighting the importance of matching pump specifications to the specific application needs.

Key factors influencing head pressure include the elevation of the discharge point and the resistance created by the system, such as pipe friction and fittings. It is essential to conduct a detailed analysis of these components before choosing a pump. The Hydraulic Institute’s data shows that inadequate assessment of head pressure can lead to over-pumping or under-pumping situations, wasting energy and reducing the system's overall efficiency. As a result, industries must prioritize accurate calculations and consider the total dynamic head (TDH) to ensure optimal pump selection and to minimize operational costs, which can result in savings of approximately 15-25% on energy expenditure in large-scale systems.

Power Consumption Considerations: Balancing Efficiency and Cost Effectiveness

When choosing a submersible pump, power consumption is a critical factor that can significantly impact both efficiency and cost-effectiveness. Selecting a pump that operates efficiently can lead to substantial savings in energy bills over time. Look for models with a high-efficiency motor, as these are designed to use less power while providing the same output. Additionally, consider the pump's duty cycle; pumps that run continuously at low speeds can often use less energy than those that frequently cycle on and off.

**Tip**: Always check for an Energy Star rating or similar certifications when selecting your submersible pump. This ensures that you are investing in a product that meets stringent efficiency guidelines.

Another important consideration is the pump's size and capacity. A pump that is too large for your application will not only waste energy but may also lead to higher wear and tear, reducing its lifespan. Evaluate your requirements carefully to choose a pump that balances capacity with energy efficiency.

**Tip**: Use flow rate calculators and consult with professionals to determine the optimal pump size for your needs to avoid over-sizing and unnecessary expenses.

Material Selection: Impact on Lifespan and Operational Effectiveness of Pumps

When selecting a submersible pump, material selection is paramount to ensure longevity and operational effectiveness. The choice of materials directly influences the pump's resistance to environmental factors such as corrosion, abrasion, and temperature fluctuations. For instance, stainless steel and certain thermoplastics are often favored for their durability and resistance to harsh chemicals. Using higher-grade materials can enhance the pump's lifespan, reducing the frequency of replacements and maintenance costs over time.

Moreover, the operational effectiveness of a pump is significantly impacted by its material composition. Pumps made with corrosion-resistant materials can handle more aggressive fluids without degrading, which is essential in applications involving sewage or chemical processing. Similarly, the ability to operate in various temperatures is crucial; for example, pumps exposed to extreme heat require materials that can withstand thermal expansion and prevent structural failure. Therefore, investing in pumps made from suitable materials not only boosts efficiency but also ensures reliable performance across a range of applications.

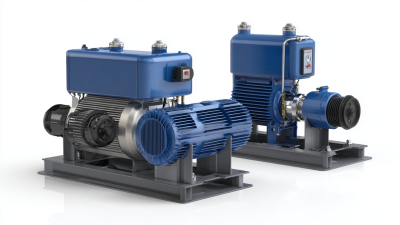

The Role of Submersible Pump Design in Preventing Clogging and Ensuring Reliability

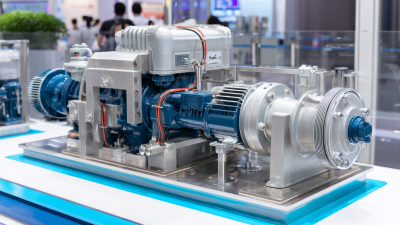

Submersible pump design plays a crucial role in preventing clogging and ensuring reliability in various applications, from residential use to industrial settings. A well-designed pump incorporates features that minimize the likelihood of debris buildup, which is essential for maintaining efficiency and prolonging the lifespan of the equipment. For instance, newer models introduced in the market focus on intelligent design aspects, such as advanced filtration systems and streamlined impeller configurations that enhance the flow of water while reducing the chances of obstruction. This innovation not only boosts the performance but also caters to the increasing demand for reliable solutions in sectors including oil, gas, and agriculture.

According to market reports, the United States submersible pumps market is expected to reach a remarkable USD 5.94 billion by 2033, driven by the need for modernization of water infrastructure and heightened productivity across multiple industries. The development of smart pump management systems further complements the trend towards efficient water management, directly addressing environmental impacts while safeguarding essential services. As technology continues to advance, selecting the right submersible pump design becomes pivotal, ensuring that users benefit from high reliability and reduced downtime, which is vital in applications where water management is critical.

Related Posts

-

Exploring Market Trends for Submersible Dirty Water Pumps at the 138th China Import and Export Fair 2025

-

The Essential Guide to Choosing the Right Submersible Pump for Your Needs

-

Transform Your Garden: The Ultimate Guide to Submersible Water Pumps for Efficient Irrigation

-

The Ultimate Guide to Understanding How Water Pumps Transform Our Daily Lives

-

What are the Key Features of Modern Irrigation Pumps?

-

Exploring Water Pump Innovations for Home Use at the 2025 China Import and Export Fair