Why You Should Choose a Deep Well Submersible Pump for Your Water Supply Needs

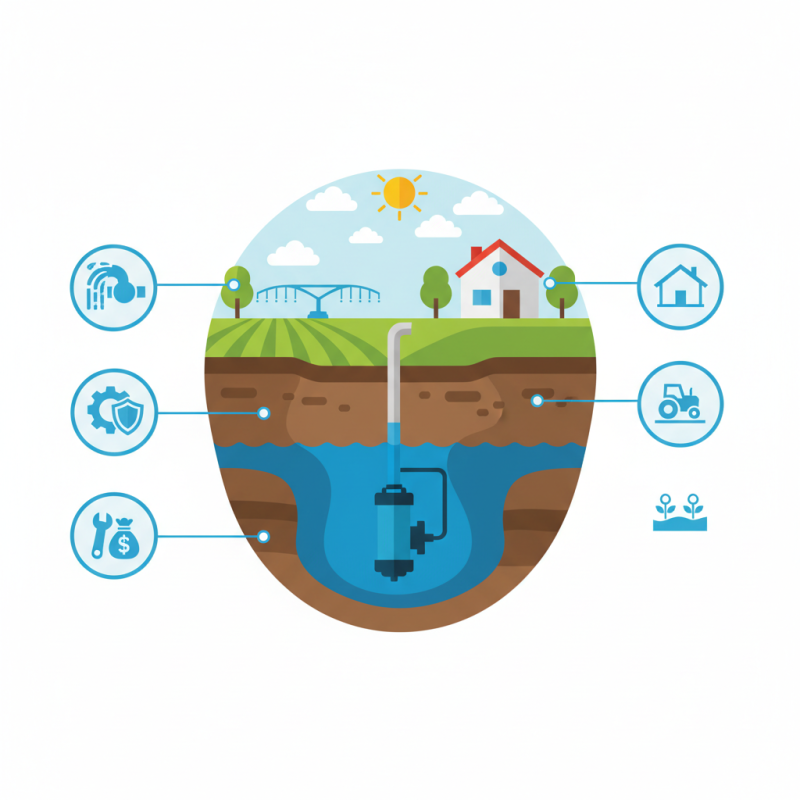

When it comes to meeting your water supply needs, the choice of pump can significantly impact efficiency, reliability, and overall performance. One option that stands out for these requirements is the deep well submersible pump. Designed to function effectively in deep water sources, these pumps offer exceptional durability and versatility, making them an ideal solution for both residential and agricultural applications. The deep well submersible pump operates submerged in water, allowing it to draw from underground aquifers without the limitations faced by traditional surface pumps.

The advantages of opting for a deep well submersible pump include their ability to deliver large volumes of water from significant depths, which is particularly beneficial in areas where water tables are low. Additionally, these pumps are engineered to withstand harsh conditions, ensuring a longer lifespan and reduced maintenance costs. As you consider the best pumping solutions for your water supply needs, exploring the benefits and features of a deep well submersible pump could be a pivotal step towards achieving reliable and efficient water access.

Benefits of Deep Well Submersible Pumps for Water Supply

Deep well submersible pumps are increasingly favored for water supply needs due to their efficiency and reliability. One of the primary benefits of these pumps is their ability to lift water from significantly greater depths compared to traditional surface pumps. This is particularly advantageous in areas where groundwater is located at considerable depths, ensuring a consistent supply of fresh water. Their design allows for operation submerged in water, which minimizes the risk of overheating and wear, leading to a longer lifespan compared to conventional pumps.

Additionally, deep well submersible pumps are known for their energy efficiency. By operating underwater, they can utilize the hydrostatic pressure of the water column to aid in the pumping process. This results in reduced energy costs, making them an eco-friendly choice for long-term water supply solutions. Furthermore, these pumps can be installed in a variety of settings, from agricultural irrigation systems to residential water supply, demonstrating their versatility in meeting diverse water needs. The quiet operation of submersible pumps also contributes to a more serene environment, making them ideal for residential areas.

Why You Should Choose a Deep Well Submersible Pump for Your Water Supply Needs - Benefits of Deep Well Submersible Pumps for Water Supply

| Feature | Description | Benefits |

|---|---|---|

| High Efficiency | Deep well submersible pumps are designed to operate submerged in water, maximizing efficiency and minimizing energy consumption. | Lower electricity costs and reduced environmental impact. |

| Durability | Made from corrosion-resistant materials, suitable for deep and harsh environments. | Longer lifespan, requiring less frequent replacements. |

| Versatility | Can pump water from various depths and sources including wells and tanks. | Adaptable to many applications, including agricultural and residential use. |

| Low Maintenance | Designed for submerged operation reduces wear and tear. | Fewer repairs and less downtime, saving time and money. |

| Quiet Operation | Operates underwater, significantly reducing noise levels compared to surface pumps. | Ideal for residential areas where noise is a concern. |

Understanding the Mechanism of Deep Well Submersible Pumps

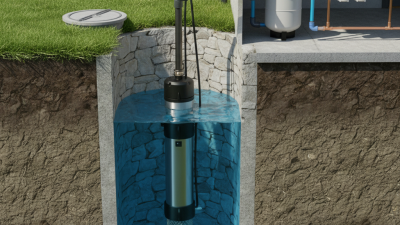

Deep well submersible pumps are essential for extracting water from deep underground sources, making them a reliable choice for both residential and agricultural water supply needs. These pumps work by being submerged directly into the water. As water enters the pump, a series of impellers spin to increase water pressure, pushing it up through the well casing to the surface. This mechanism allows for efficient water transport, with the capability to reach depths that traditional pumps cannot.

When considering a deep well submersible pump, it’s crucial to evaluate the pump's horsepower and the depth of your well. Incorrect horsepower may lead to insufficient water supply, while an excessive horsepower could drain energy resources and increase operational costs.

Tips: Regular maintenance of your deep well submersible pump can extend its lifespan. Ensure to check for any signs of wear or corrosion, as well as timely cleaning of the pump to prevent clogs. Additionally, investing in a quality pressure switch can help regulate the pump's operation, leading to improved efficiency and functionality.

Key Features to Consider When Choosing a Submersible Pump

When selecting a deep well submersible pump for your water supply needs, it's crucial to consider several key features to ensure you make the right choice. One of the primary aspects to examine is the pump's capacity and flow rate. According to the American Water Works Association, a submersible pump should match the water demand of your household or application, ideally providing a flow rate that meets or exceeds 10 gallons per minute for residential use. This ensures that the pump operates efficiently without running dry or overheating.

Another important feature to consider is the material of the pump. High-quality stainless steel is often recommended for its durability and resistance to corrosion, making it suitable for various water conditions. A recent study by the Water Research Foundation indicates that non-corrosive materials can extend the life of a submersible pump by up to 50%. Moreover, it's essential to check the pump's wattage and efficiency ratings. Opting for energy-efficient models can lead to significant cost savings over time, as they consume less electricity, benefiting both your wallet and the environment.

Tips: Prior to making a purchase, assess the depth of your well and the type of fluid being pumped. This information will guide you in choosing a pump with the appropriate horsepower. Additionally, consider consulting with local experts to ensure your selected pump complies with regional regulations and performs optimally in your specific water conditions. Remember, investing in the right submersible pump not only guarantees reliable water supply but also contributes to long-term efficiency and sustainability.

Applications of Deep Well Submersible Pumps in Various Settings

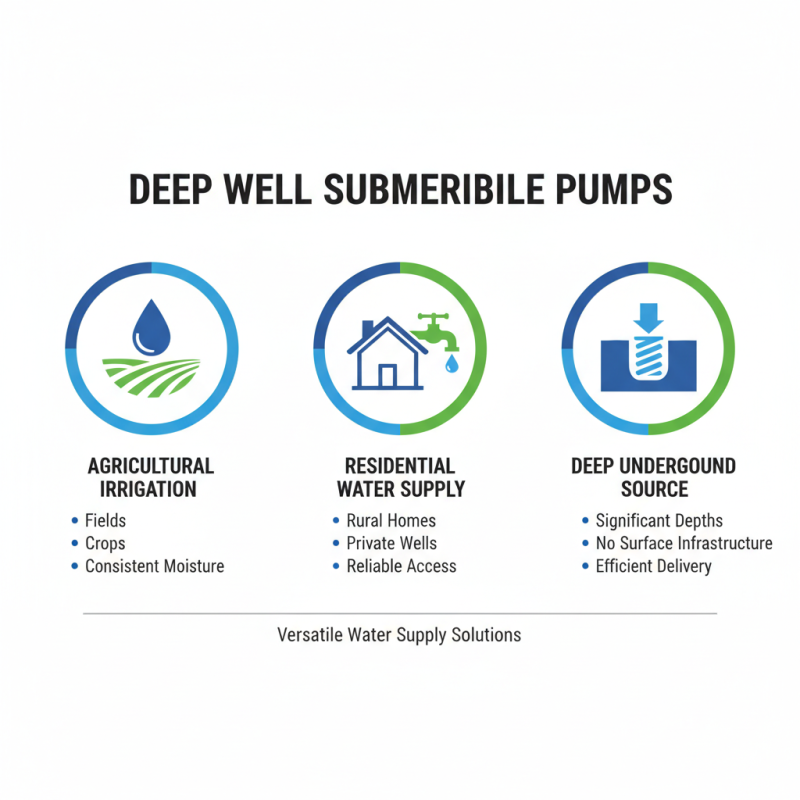

Deep well submersible pumps offer a versatile solution for a range of water supply needs across various settings. In agricultural applications, these pumps are essential for irrigation purposes, delivering water efficiently from deep underground to fields that require consistent moisture. Additionally, they are commonly used in residential settings to supply water to homes, especially in rural areas where access to municipal water sources is limited. Their ability to operate at significant depths makes them a preferred choice for users needing reliable water access without extensive surface infrastructure.

In industrial environments, deep well submersible pumps play a crucial role in managing water for manufacturing processes, cooling systems, and wastewater management. Their robust design allows them to handle demanding conditions, making them suitable for construction sites where groundwater management is necessary. Proper installation and regular maintenance can enhance the longevity and performance of these pumps, ensuring that they continue to meet the demands of diverse applications.

**Tips:** When considering a deep well submersible pump, assess the depth of your water source and the necessary flow rate to determine the right specifications for your needs. Regularly check for signs of wear or inefficiency to maintain optimal performance and avoid costly repairs or replacements. It’s also beneficial to consult with a professional for proper installation and to ensure compliance with local regulations.

Maintenance Tips for Optimal Performance of Deep Well Pumps

Maintaining a deep well submersible pump is crucial for ensuring its optimal performance and longevity. Regular maintenance should start with routine inspections. Check for any signs of wear or damage on the pump’s components, such as the motor and impeller. Additionally, periodically inspect the electrical connections to ensure they are secure and free from corrosion. This proactive approach can help identify potential issues before they escalate, thus minimizing downtime and repair costs.

Another vital aspect of maintenance involves monitoring the water quality being pumped. Sediment and debris can accumulate over time, leading to decreased efficiency and possible damage to the pump. Implementing a filtration system can significantly reduce these risks by preventing larger particles from entering the pump. Furthermore, ensure that the discharge line is clear and free of obstructions, as this helps maintain the pump's operational efficiency. Regularly flushing the system can also help prevent clogs and enhance water flow, ultimately contributing to the pump's overall health and performance.

Deep Well Submersible Pump Performance vs. Maintenance Frequency

This chart illustrates the correlation between maintenance frequency and the performance of deep well submersible pumps. Regular maintenance can significantly enhance efficiency and prolong the lifespan of the equipment.

Related Posts

-

How to Choose the Right Submersible Well Pump for Your Home Needs

-

Unlocking Opportunities in Submersible Well Pump Market at the 2025 China Import and Export Fair

-

Innovative Uses of Small Water Pumps in Modern Agriculture Boosting Efficiency and Sustainability

-

Understanding the Essential Role of Small Water Pumps in Everyday Life and Gardening

-

Exploring the Best Deals on Water Pump Prices for 2024 Essentials

-

Maximizing Efficiency: Choosing the Best Deep Well Water Pump for Your Needs