The Essential Guide to Choosing the Right Submersible Pump for Your Needs

Choosing the right submersible pump for your needs is a critical decision that can significantly impact your project’s efficiency and cost-effectiveness. According to the latest market analysis by Global Industry Analysts, Inc., the global submersible pump market is projected to reach a staggering USD 19.3 billion by 2027, growing at a CAGR of 5.2% during the forecast period. This growth is driven by escalating demand in water and wastewater management, agriculture, and mining industries, where reliable water extraction is paramount.

Choosing the right submersible pump for your needs is a critical decision that can significantly impact your project’s efficiency and cost-effectiveness. According to the latest market analysis by Global Industry Analysts, Inc., the global submersible pump market is projected to reach a staggering USD 19.3 billion by 2027, growing at a CAGR of 5.2% during the forecast period. This growth is driven by escalating demand in water and wastewater management, agriculture, and mining industries, where reliable water extraction is paramount.

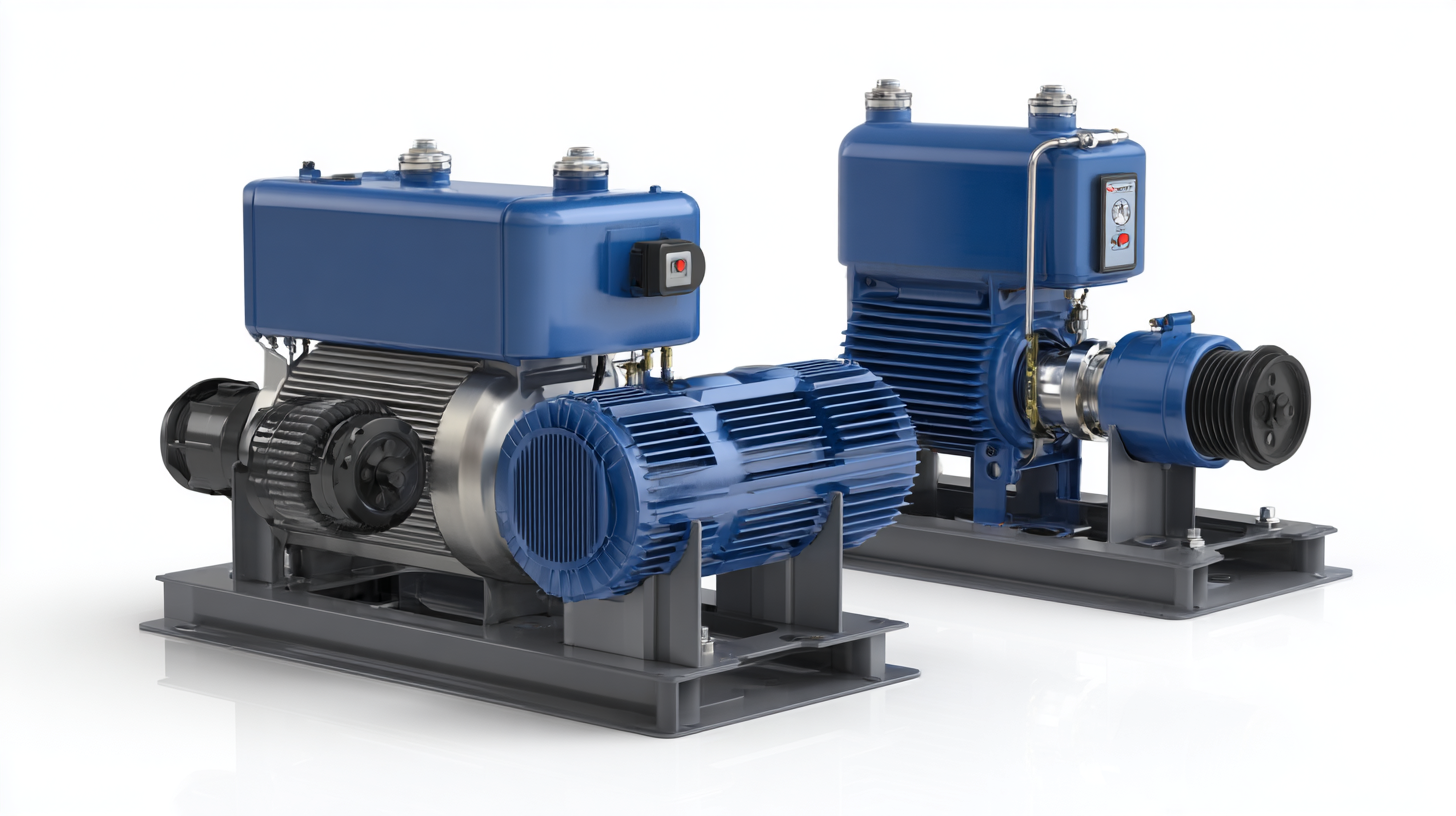

The versatility of submersible pumps makes them suitable for various applications, from residential to industrial uses. However, with the diverse types available—ranging from sewage pumps to borehole pumps—understanding the specifics of each type and their corresponding applications is essential in ensuring optimal performance and longevity. Thus, an informed selection can not only enhance operational efficiencies but also lead to substantial savings in maintenance and energy costs.

Understanding Submersible Pumps: Types and Applications

Submersible pumps are vital for a variety of applications, ranging from residential drainage to industrial water processing. Understanding the different types of submersible pumps—such as sewage pumps, drainage pumps, and deep well pumps—can significantly impact their efficiency and longevity. According to a report by Research and Markets, the global submersible pump market is expected to grow from $8.2 billion in 2022 to $13.7 billion by 2028, indicating an increasing reliance on these devices across multiple sectors.

When selecting a submersible pump, consider your specific needs. For instance, sewage pumps are designed to handle solids and can be crucial for wastewater management. On the other hand, drainage pumps are excellent for removing water from flooded areas or construction sites. Additionally, deep well pumps are essential for accessing groundwater at significant depths. Selecting the correct type based on the application can prevent operational failures and improve efficiency.

**Tips:**

1. Always check the pump’s horsepower and flow rate to ensure it meets your needs.

2. Consider the pump material, such as stainless steel or thermoplastic, for durability against the liquids being pumped.

3. Don't underestimate the importance of proper installation; consult a professional if you're unsure about the setup to avoid costly mistakes.

Key Factors to Consider When Selecting a Submersible Pump

When selecting a submersible pump, several key factors must be considered to ensure optimal performance for your specific needs. First, the type of fluid the pump will handle is crucial. Whether you're pumping clean water, slurry, or a more challenging mixture, the pump's design must accommodate its viscosity, temperature, and potential contaminants. For example, in sectors like mining, where slurry pumps are vital, understanding the characteristics of the mixture can prevent operational issues and extend the pump's lifespan.

Another important factor is the pump's capacity and efficiency ratings. Proper sizing ensures that the pump can handle the required flow rate while minimizing energy consumption. In sectors such as aquaculture and municipal water systems, the efficiency of the pump not only impacts operational costs but also has implications for sustainability. As industries strive to reduce their carbon footprint, selecting a pump with high energy efficiency becomes increasingly essential. Additionally, considerations like installation, maintenance requirements, and the pump's compatibility with existing infrastructure are fundamental to making an informed choice.

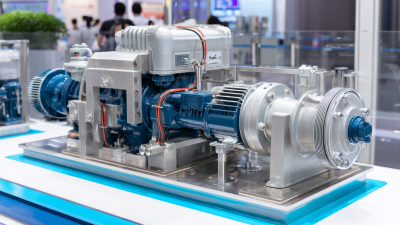

Evaluating Pump Specifications: Power, Depth, and Flow Rate

When selecting a submersible pump, it is crucial to evaluate key specifications including power, depth, and flow rate. According to industry reports, optimal performance is often influenced by the pump's efficiency at varying depths, especially in applications like hydrogeothermal energy systems, where effective pumping from depths greater than 1500 m can significantly enhance heating solutions in district heating scenarios. The expected temperature ranges of less than 200 °C at these depths add another layer of complexity, requiring pumps that maintain high efficiency even under demanding thermal conditions.

Moreover, the flow rate directly impacts the operational efficacy of submersible pumps. In recent studies, it was established that balancing flow rate with energy demand can lead to substantial energy savings, as found in research focused on real-time monitoring in pumping stations. These findings suggest that integrating intelligent control systems that adjust flow based on seasonal needs and thermal recovery strategies can boost overall system performance. As the market evolves with advancements in technology, the optimal selection of a submersible pump must thoroughly consider these critical specifications to ensure operational success and sustainability in energy-intensive applications.

Maintenance and Care Tips for Longevity of Submersible Pumps

When it comes to maintaining submersible pumps, proper care is crucial for ensuring longevity and optimal performance. Regular maintenance checks are vital to keep your pump functioning efficiently. One of the most important tips is to inspect the power cord for any signs of wear or damage. A frayed or damaged cord can not only impede performance but also present a safety hazard. Always ensure that the pump is disconnected from the power supply before performing any maintenance.

Another key aspect of pump care is performance monitoring. Keep an eye on the operational noise level and vibration while the pump is in use. If you notice any unusual sounds or excessive vibrations, it may indicate a problem that requires immediate attention. Additionally, ensure that the pump is periodically cleaned to prevent debris build-up, which can lead to clogging and reduced efficiency. Regularly checking the intake screen and cleaning it if necessary can prolong the lifespan of your submersible pump. Remember, a little preventive maintenance goes a long way in keeping your pump running smoothly for years to come.

Common Myths and Misconceptions About Submersible Pumps

When it comes to submersible pumps, several myths and misconceptions cloud potential buyers' understanding and decision-making. One prevailing myth is that all submersible pumps are equally efficient for all tasks. In reality, selecting the correct pump relates to specific applications, including the type of fluid being moved, depth requirements, and flow rates. According to industry data, matching pump specifications to system needs can improve energy efficiency by up to 30%, demonstrating that understanding the nuances of submersible pumps is crucial for optimal performance.

Another common myth is that submersible pumps are inherently noisy. While older models might have had this issue, advancements in technology have significantly reduced operational noise levels. Modern submersible pumps utilize quieter motor designs and vibration-dampening materials, making them suitable for residential areas without adding excessive sound pollution. Reports indicate that noise levels for new models can be as low as 40 decibels, comparable to a quiet refrigerator, which makes them more user-friendly for consumers who may have previously avoided them due to concerns about noise.

The Essential Guide to Choosing the Right Submersible Pump for Your Needs

| Feature | Details | Common Myths | Facts |

|---|---|---|---|

| Power Source | Electric and Gasoline options available | Submersible pumps can only be electric. | Many models operate on gasoline for heavier applications. |

| Flow Rate | Ranges from 5 GPM to over 200 GPM | A higher flow rate always means better performance. | The right flow rate depends on your specific needs and conditions. |

| Head Height | Vertical lift capability measures up to 40 feet | Pumps can’t operate effectively at heights over 10 feet. | Most submersible pumps can handle much higher lifts when properly rated. |

| Applications | Used in residential, agricultural, and industrial settings | Only for draining and dewatering. | Can also be used for irrigation, wastewater management, and more. |

| Maintenance | Periodic checks required for longevity | Submersible pumps are maintenance-free. | Regular maintenance is crucial to ensure optimal performance. |

Related Posts

-

Exploring Market Trends for Submersible Dirty Water Pumps at the 138th China Import and Export Fair 2025

-

Unlocking Opportunities in Submersible Well Pump Market at the 2025 China Import and Export Fair

-

Exploring Water Pump Innovations for Home Use at the 2025 China Import and Export Fair

-

What are the Key Features of Modern Irrigation Pumps?