Top 10 Dirty Water Pumps: Efficient Solutions for Heavy-Duty Water Removal in 2023

In the ever-evolving landscape of construction and industrial operations, the demand for reliable and efficient water removal solutions has surged, particularly in environments dealing with contaminated water. As industries adapt to climate challenges and increased flood risks, top-quality dirty water pumps have become indispensable tools in managing excess water. A recent report by the Global Pump Market Research indicates that the dirty water pump segment is projected to witness a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030, driven by ongoing infrastructure development and the need for efficient wastewater management systems.

Industry expert Dr. Emily Thornton, a leading authority on water management solutions, emphasizes the critical need for advanced pumping technologies in her statement: "Investing in high-performance dirty water pumps is not just a choice; it's a necessity for ensuring operational efficiency and safeguarding against potential water-related damages."

This assertion underscores the importance of selecting robust and effective pumps that can handle the rigors of tough working conditions, which are often characterized by heavy sediments and contaminants.

As we delve into the top ten dirty water pumps for 2023, it’s essential to consider not only their efficiency and durability but also their role in promoting sustainability and resilience within various sectors. The evolution of pump technology means that industries can now benefit from solutions designed to tackle the unique challenges posed by contaminated water, making informed choices critical for successful water management strategies.

The Importance of Choosing the Right Dirty Water Pump for Heavy-Duty Tasks

When it comes to heavy-duty water removal tasks, selecting the right dirty water pump is crucial. The appropriate pump not only enhances efficiency but also ensures the longevity of the equipment. Factors such as the pump's capacity, power, and type of impeller can greatly impact its performance in challenging conditions like construction sites or flooded areas. It is essential to analyze the specific requirements of the job at hand and choose a pump designed to handle the volume and type of debris expected.

Tips: Always check the pump’s horsepower and flow rate specifications before making a purchase. A higher horsepower typically translates to better performance, especially in demanding environments. Additionally, consider models with a vortex impeller, which can handle larger solids without clogging, making them ideal for dirty water settings.

Another important aspect is the pump's portability and ease of use. A lightweight, easily maneuverable pump can save time and effort, particularly in emergency situations. Furthermore, pay attention to the construction material of the pump—durable, corrosion-resistant materials can significantly increase the lifespan of the pump, reducing maintenance costs long-term.

Key Features to Consider in the Best Dirty Water Pumps of 2025

When considering the best dirty water pumps for heavy-duty water removal, it's imperative to focus on key features that enhance efficiency and reliability. In 2025, several attributes will define the top choices in the market. First, pump power and flow rate are crucial; opt for models that provide higher horsepower and can move a significant volume of water per minute. This ensures they can handle substantial tasks like draining flooded basements or clearing stagnant water swiftly.

Another essential feature is the pump's buildup tolerance. Pumps with better filtration systems can handle larger debris without clogging or failure. Look for models with durable materials and corrosion-resistant components to withstand harsh environments. Additionally, portability and ease of use are vital; lightweight designs with ergonomic handles and convenient cord lengths can make operation simpler and more accessible, especially in emergency situations or when transferring water across large areas. Emphasizing these features will help consumers select the most effective dirty water pump for their needs in the coming years.

Top 10 Dirty Water Pumps: Efficiency Comparison

Top Models Reviewed: Performance, Durability, and Efficiency

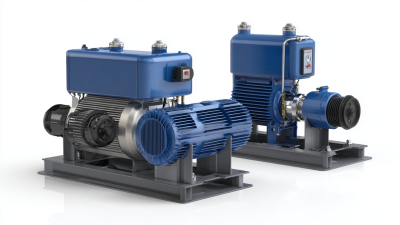

When considering the best dirty water pumps for 2023, performance, durability, and efficiency stand out as crucial factors. The top models available on the market today have been meticulously designed to handle heavy-duty water removal tasks, ensuring that you can tackle even the toughest challenges. Each pump's motor power and flow rate are essential indicators of how quickly and efficiently it can remove water, making them ideal for construction sites, flooded basements, and agricultural projects.

Tips for selecting the right dirty water pump include assessing the specific requirements of your job. Look for pumps with stainless steel or durable plastic housing to withstand harsh conditions. Additionally, pay attention to the pump's maximum head height and flow rate to ensure it meets your project's demands. Regular maintenance, such as checking filters and impellers, can also prolong the life of your pump and maintain its efficiency.

Furthermore, consider investing in models that offer features like automatic shut-off and thermal overload protection, which enhance safety and convenience during operation. By taking the time to evaluate these elements, you’ll be better equipped to choose a pump that not only performs well but also stands up to heavy use over time.

Comparative Analysis of Pricing and Value for 2025’s Best Options

As we look ahead to 2025, the market for heavy-duty water removal is evolving, and consumers are presented with a multitude of options for dirty water pumps. A comparative analysis of the pricing and value of the top models reveals critical insights for potential buyers. The competition among brands is fierce, with varying features aimed at maximizing efficiency and durability. Consumers need to evaluate not only the cost but also the performance metrics that define each pump’s capabilities.

In analyzing these pumps, aspects such as flow rate, discharge head, and motor power play a vital role in determining value for money. Some models may be priced higher but offer superior technology that allows for faster and more efficient water removal, making them a worthwhile investment. On the other hand, more budget-friendly options may still perform adequately for smaller tasks. As we delve into the best options available in 2025, understanding these nuances will empower consumers to make informed decisions that align with their specific needs and budgets.

Expert Tips for Maintenance and Longevity of Your Dirty Water Pump

When it comes to maintaining the longevity of your dirty water pump, adopting the right maintenance practices is crucial. The 2023 industry report from the Water Management Institute notes that approximately 30% of utility failures can be attributed to improper maintenance of pumping systems. Regularly inspecting your pump for signs of wear, such as frayed cables or rusted components, can prevent costly breakdowns and extend its operational life significantly. Additionally, ensuring that the pump is used within its design specifications is essential; overloading can lead to overheating and eventual failure.

Moreover, proper storage plays a pivotal role in the maintenance of dirty water pumps. According to a survey conducted by Pump Manufacturers Association, nearly 25% of pumps fail due to inadequate storage conditions. Keeping pumps in a dry, climate-controlled environment can mitigate the risks of corrosion and other environmental damage. Furthermore, routinely cleaning the pump and the surrounding area can help prevent debris from entering the pump, which can interfere with performance. Following these expert tips can ensure that your dirty water pump remains efficient and performs at its best for years to come.

Related Posts

-

5 Essential Tips for Choosing the Right Flood Pump for Your Home Needs

-

Exploring Market Trends for Submersible Dirty Water Pumps at the 138th China Import and Export Fair 2025

-

Innovative Uses of Small Water Pumps in Modern Agriculture Boosting Efficiency and Sustainability

-

Understanding the Essential Role of Small Water Pumps in Everyday Life and Gardening

-

What are the Key Features of Modern Irrigation Pumps?

-

The Essential Guide to Choosing the Right Submersible Pump for Your Needs