Top 5 Drainage Pumps for Efficient Water Removal: A Comprehensive Buyer’s Guide

In the realm of water management, the significance of a reliable drainage pump cannot be overstated. According to a report by Market Research Future, the global market for drainage pumps is projected to grow at a CAGR of 4.5% between 2021 and 2027, reflecting an increasing demand driven by industrial, agricultural, and urban development needs. Effective water removal solutions are crucial not only in preventing water damage in residential and commercial spaces but also in managing stormwater and wastewater effectively.

With a variety of options available, selecting the right drainage pump becomes essential for ensuring efficiency and reliability. This article explores the top five drainage pumps, providing readers with a comprehensive buyer's guide that highlights critical features, performance metrics, and user considerations, empowering consumers to make informed decisions in their water management strategies.

Top Features to Look for in Drainage Pumps for Optimal Performance

When choosing a drainage pump, it's essential to focus on key features that ensure optimal performance.

First and foremost, consider the pump's horsepower and flow rate. A more powerful pump can handle larger volumes of water quickly,

making it ideal for emergencies or heavy rainfall situations. Additionally, the capability to handle solids is crucial;

look for pumps with a semi-vortex or vortex impeller design,

which allows them to efficiently pass debris without clogging.

When choosing a drainage pump, it's essential to focus on key features that ensure optimal performance.

First and foremost, consider the pump's horsepower and flow rate. A more powerful pump can handle larger volumes of water quickly,

making it ideal for emergencies or heavy rainfall situations. Additionally, the capability to handle solids is crucial;

look for pumps with a semi-vortex or vortex impeller design,

which allows them to efficiently pass debris without clogging.

Another important feature is the pump's durability and construction material. Pumps made from corrosion-resistant materials, such as stainless steel or thermoplastic, will last longer in harsh environments. Also, consider the ease of maintenance; pumps with a simple design allow for quicker inspections and repairs, reducing downtime. Lastly, automatic shut-off switches and float systems enhance convenience, providing peace of mind by preventing overflow and damage. Knowing these key features will empower you to make an informed choice when selecting the right drainage pump for your needs.

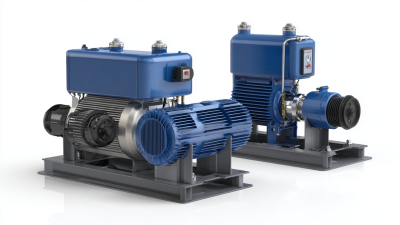

Understanding Different Types of Drainage Pumps: Submersible vs. Surface

When navigating the world of drainage pumps, it’s essential to understand the distinct categories available, primarily submersible and surface pumps.

Submersible pumps are designed to operate underwater, making them ideal for removing water from deep basements or flooded areas.

According to a recent market analysis by Research and Markets, the submersible pump segment is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2028, driven by increased demand in residential and commercial applications.

In contrast, surface pumps, which are installed above ground, pull water from a source, such as a well or a sump.

They are generally more affordable and easier to maintain than their submersible counterparts. However, surface pumps can be less effective in situations where high volumes of water need to be removed quickly, particularly in deep locations.

A 2022 report from Statista noted that surface drainage pumps hold approximately 30% of the total market share, indicating a robust demand but also highlighting the limitations in specific use cases, such as large-scale flooding events.

Understanding these differences is crucial for selecting the appropriate pump to ensure efficient water removal in various scenarios.

Key Industry Metrics: Flow Rate, Head Height, and Power Consumption Explained

When selecting a drainage pump, understanding key industry metrics is crucial for ensuring efficient water removal.

The flow rate, measured in

gallons per minute (GPM), indicates how quickly water can be pumped away. A higher flow rate is

essential for situations where rapid water removal is necessary, such as during flooding or in

construction sites. It’s important to match the pump's flow rate with the specific needs of your

application to maximize efficiency.

Maintenance Tips to Enhance the Lifespan of Your Drainage Pump

When it comes to ensuring the longevity and optimal performance of your drainage pump, regular maintenance is key. According to a report by the American Society of Plumbing Engineers, neglecting regular upkeep can reduce pump efficiency by as much as 25%, leading to increased energy costs and potential equipment failure. Ensuring that your drainage pump is free from debris and sediment buildup can significantly improve its function. Routine inspections should be conducted at least twice a year to check for clogs, leaks, and corrosion.

In addition to physical checks, lubricating moving parts and replacing worn-out components are crucial for enhancing lifespan. The National Pump Manufacturers Association suggests that a well-maintained pump can last upwards of 15 years, while poorly maintained units may fail within 5 years. Utilizing quality parts during replacements and adhering to the manufacturer’s specifications can further prolong the pump’s efficiency. By prioritizing these maintenance practices, users can not only extend their pump’s operational life but also maintain peak performance, ensuring effective water removal when it is most needed.

Comparative Analysis of Leading Brands in the Drainage Pump Market

The drainage pump market has become increasingly vital for both residential and industrial applications, driven by the need for effective water management solutions. Recent analyses reveal that the North America utility pump market is expected to grow significantly, with a focus on product types such as transfer pumps, submersible pumps, and dewatering pumps. Specifically, the demand for submersible sump pumps is projected to increase due to their efficiency in water removal in tight spaces, crucial for flood-prone areas.

In addition, the global sewage pump market demonstrates robust growth, with some reports indicating a noteworthy value surpassing USD 220 million. This surge can be attributed to the rising concerns regarding wastewater management and the need for efficient, durable pumping systems in both urban and rural settings. The competitive landscape is intensifying as manufacturers innovate, driven by trends towards energy-efficient and environmentally-friendly pumping solutions, which are becoming a priority among consumers seeking sustainable options for their water management needs.

Top 5 Drainage Pumps for Efficient Water Removal

| Model | Power (HP) | Maximum Flow Rate (GPH) | Maximum Head (Feet) | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 1/2 | 3,600 | 20 | 25 | 150 |

| Model B | 1 | 4,400 | 25 | 30 | 225 |

| Model C | 3/4 | 5,280 | 30 | 35 | 200 |

| Model D | 1.5 | 6,000 | 35 | 50 | 350 |

| Model E | 2 | 7,200 | 40 | 60 | 400 |

Related Posts

-

What are the Key Features of Modern Irrigation Pumps?

-

The Essential Guide to Choosing the Right Submersible Pump for Your Needs

-

Unlocking Opportunities in Submersible Well Pump Market at the 2025 China Import and Export Fair

-

Exploring Market Trends for Submersible Dirty Water Pumps at the 138th China Import and Export Fair 2025

-

Exploring Water Pump Innovations for Home Use at the 2025 China Import and Export Fair