Top Industrial Water Pump Types You Need to Know for Your Business

When it comes to maintaining efficient operations in various industrial sectors, understanding the types of industrial water pumps available is crucial. These pumps play a pivotal role in fluid transportation, making them essential components in processes ranging from manufacturing to waste management. By selecting the right kind of industrial water pump, businesses can ensure optimal performance, reliability, and energy efficiency, ultimately contributing to the bottom line.

In this overview, we will explore the top types of industrial water pumps that cater to diverse applications and operational needs. From centrifugal pumps known for their versatility to diaphragm pumps that excel in specific tasks, each type comes with distinct characteristics and advantages. Understanding these differences will equip businesses with the knowledge necessary to make informed decisions for their operations, enhancing productivity and minimizing downtime. Whether you’re looking to upgrade existing systems or invest in new technology, recognizing the crucial role of industrial water pumps is the first step toward streamlining your business processes.

Overview of Industrial Water Pump Applications in Various Sectors

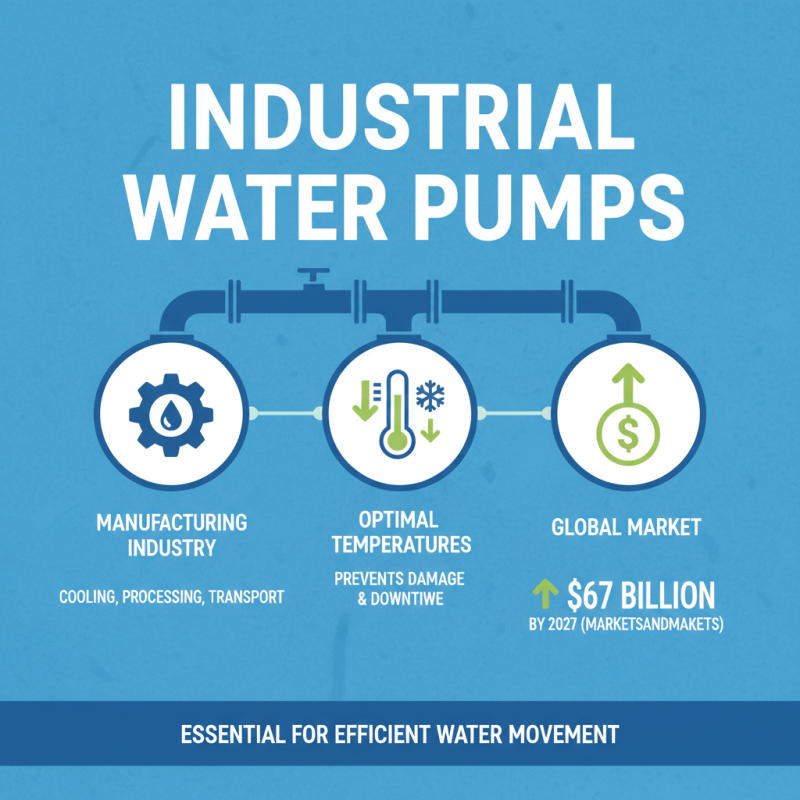

Industrial water pumps are essential components across various sectors, playing a critical role in the efficient movement of water for multiple applications. In the manufacturing industry, for example, pump systems are used for cooling, processing, and transporting water, with the global industrial pump market set to reach approximately $67 billion by 2027, according to a recent report by MarketsandMarkets. These pumps ensure that operations run smoothly and help in maintaining optimal temperatures, thus preventing equipment damage and downtime.

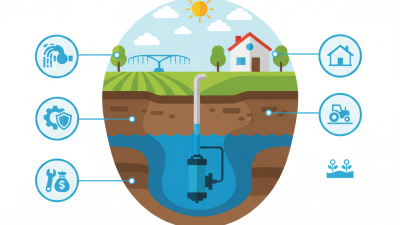

In the agricultural sector, water pumps are indispensable for irrigation and livestock watering. The growth in precision agriculture, which is projected to reach a market value of $10 billion by 2025, relies heavily on effective water management techniques. Industrial water pumps facilitate the rapid distribution of water resources, thereby increasing crop yield and ensuring that farmers can respond swiftly to changing weather conditions. Furthermore, in the energy sector, pumps are crucial for transferring water in cooling processes and managing wastewater, highlighting their versatility and importance across diverse industrial applications. The ability to handle various water types and pressures makes industrial pumps integral not just for operational efficiency but also for environmental sustainability within these industries.

Types of Centrifugal Pumps and Their Unique Benefits for Businesses

Centrifugal pumps are vital components in various industrial applications, valued for their efficiency and versatility. One prominent type is the single-stage centrifugal pump, which is designed for pumping large volumes of fluids with low viscosity. These pumps are ideal for straightforward applications, such as irrigation or water supply. Their simple construction allows for easy maintenance, making them a cost-effective choice for businesses looking to optimize operational efficiency.

Another significant category is the multi-stage centrifugal pump, which consists of multiple impellers stacked in series. This design enables these pumps to generate higher pressures, making them suitable for demanding tasks such as boiler feedwater or high-pressure cleaning operations. Businesses benefit from the ability to handle challenging applications without compromising on flow rate or pressure, ensuring a reliable performance even in intensive environments.

Finally, self-priming centrifugal pumps offer an essential benefit for industries where the water source may be located below the pump level. They can effectively draw liquid into the pump without requiring manual priming, reducing downtime and labor costs. This feature is particularly advantageous in applications like wastewater treatment and construction sites, where ease of use and reliability are paramount. By understanding the unique benefits of these centrifugal pump types, businesses can make informed decisions that enhance their operational efficiencies.

Top Industrial Water Pump Types You Need to Know for Your Business

The above chart illustrates the various types of industrial water pumps and the number of applications associated with each type. Centrifugal pumps dominate the market due to their versatility and efficiency, while other types like positive displacement and submersible pumps also play significant roles in specialized applications.

Understanding Positive Displacement Pumps and Their Uses in Industry

Positive displacement pumps play a crucial role in various industrial applications, known for their ability to move fluids at a consistent flow rate regardless of changes in pressure. According to a report by Global Market Insights, the positive displacement pump market is projected to reach approximately $10 billion by 2025, driven by their utilization in industries such as oil and gas, chemical processing, and water management. These pumps operate by trapping a fixed volume of fluid and then forcing it into the discharge pipe, making them ideal for handling high-viscosity liquids and slurries.

In the chemical processing industry, for example, positive displacement pumps are essential for transferring aggressive fluids with precision. A study published in the Journal of Chemical Engineering highlighted that implementing these pumps can increase efficiency by up to 15% compared to centrifugal pumps when dealing with highly viscous substances. Additionally, their robust design allows them to handle fluctuating pressures and varying flow requirements, making them a preferred choice in many applications ranging from food processing to wastewater treatment where maintaining flow consistency is vital.

The versatility of positive displacement pumps continues to solidify their importance across different sectors, ensuring operational reliability and efficiency.

Key Factors to Consider When Choosing the Right Water Pump

When selecting the right water pump for your industrial needs, it's essential to assess several key factors to ensure optimal performance and efficiency. First and foremost, understanding the specific application of the pump is crucial. Different processes will require different types of pumps, such as centrifugal pumps for high flow rates or positive displacement pumps for high viscosity fluids. Clearly identifying the type of fluid being pumped, including its temperature, viscosity, and the potential for solids within the liquid, will guide your choice in pump technology.

Another significant factor to consider is the pump's capacity and pressure requirements. Evaluating the flow rate necessary for your operations will help determine the size and power of the pump. Additionally, the total dynamic head (TDH) must be calculated to ensure the pump can handle the height and pressure needed for system efficiency. Energy efficiency is also critical; selecting a pump that minimizes energy consumption will reduce operational costs and contribute to sustainability efforts. Finally, consider the ease of maintenance and accessibility for repairs to ensure long-term reliability and performance of the water pump in your operations.

Maintenance Best Practices for Industrial Water Pumps to Enhance Longevity

Maintaining industrial water pumps is crucial for ensuring their longevity and optimal performance. Regular maintenance practices not only enhance the efficiency of pumps but also prevent costly downtimes.

One of the primary best practices is to perform routine inspections. These inspections should include checking for leaks, ensuring that seals and gaskets are intact, and monitoring for unusual noises or vibrations that may indicate underlying issues.

Additionally, cleaning the pumps and their components is essential to remove debris and prevent corrosion.

Another vital aspect of pump maintenance is lubrication. Ensuring that bearings and moving parts are well-lubricated reduces friction and wear, contributing to a longer lifespan.

It’s important to follow the manufacturer's recommendations regarding the type and frequency of lubrication. Furthermore, keeping an eye on fluid levels and quality can prevent pump damage;

contaminated fluids can cause significant wear on pump components. Implementing a proactive maintenance schedule, which includes replacing worn parts before they fail, will significantly enhance the overall reliability and durability of industrial water pumps.

Related Posts

-

Unlocking Opportunities in Submersible Well Pump Market at the 2025 China Import and Export Fair

-

What are the Key Features of Modern Irrigation Pumps?

-

Why You Should Choose a Deep Well Submersible Pump for Your Water Supply Needs

-

Exploring Market Trends for Submersible Dirty Water Pumps at the 138th China Import and Export Fair 2025

-

Innovative Uses of Small Water Pumps in Modern Agriculture Boosting Efficiency and Sustainability

-

2025 Ultimate Guide: What to Expect for Water Pump Prices and Buying Tips