Top 10 Industrial Water Pumps for Efficient Water Management Solutions

In the realm of industrial operations, efficient water management is crucial for sustaining productivity and minimizing costs. As industries continue to advance, the demand for dependable and high-performance industrial water pumps has surged. These pumps play a pivotal role in a multitude of applications, including irrigation, wastewater treatment, and cooling systems, ensuring that facilities can manage their water resources effectively.

This article explores the top 10 industrial water pumps that stand out for their reliability, efficiency, and innovative features. By selecting the right industrial water pump, organizations can enhance their operational efficiency, reduce energy consumption, and comply with environmental regulations. As we delve into these options, we aim to provide insights into how each pump can contribute to effective water management solutions, helping industries navigate the complexities of water usage while optimizing their overall performance.

Overview of Industrial Water Pumps and Their Applications

Industrial water pumps play a crucial role in various sectors, ensuring efficient management of water resources across applications such as agriculture, construction, and manufacturing. According to a recent market analysis by Research and Markets, the industrial water pump market is projected to reach USD 62 billion by 2027, highlighting the increasing demand for effective water management solutions. These pumps are designed to handle diverse water types, including freshwater, wastewater, and even corrosive materials, making them vital for maintaining operational efficiency in industrial processes.

The applications of industrial water pumps are extensive, ranging from irrigation systems in agriculture to cooling equipment in power plants. For instance, in the mining industry, pumps are essential for dewatering operations, effectively removing groundwater to enable the extraction of minerals. Moreover, recent data from the Global Water Resources report indicates that an investment in modern water management equipment, including pumps, can lead to a reduction in water wastage by up to 30%, underlining the importance of choosing the right pump for specific operational requirements. These pumps not only facilitate the movement of water but also contribute to sustainable practices by optimizing water usage and minimizing environmental impact.

Key Features to Consider When Selecting Industrial Water Pumps

When selecting industrial water pumps, several key features must be considered to ensure efficient water management solutions. First and foremost, the pump's flow rate and pressure capabilities are critical. According to a recent industry report by the Hydraulic Institute, the global market for water pumps is expected to reach $100 billion by 2025, driven by the increasing need for efficient water systems across various sectors, including agriculture, manufacturing, and municipal operations. Understanding the specific requirements of your application will allow you to choose a pump that meets or exceeds the necessary flow rate and pressure, ensuring optimal performance.

Another vital aspect to consider is the material construction of the pump. The right material will depend on the characteristics of the fluids being handled. For instance, if the pump is used for corrosive or abrasive liquids, options such as stainless steel or high-grade polymers are recommended. A report by Research and Markets highlights that corrosion-resistant pumps are projected to grow in demand due to their longevity and lower maintenance costs, particularly in industries like chemical processing and mining. Additionally, considerations around energy efficiency, compliance with environmental regulations, and ease of maintenance can significantly impact both operational costs and environmental sustainability. Employing pumps that feature advanced technology, such as variable frequency drives, can lead to energy savings of up to 30%, making energy efficiency a key factor in the selection process.

Top 10 Industrial Water Pumps for Efficient Water Management

Efficient water management is crucial across various industries, with industrial water pumps playing a pivotal role in the process. According to a recent report by the International Water Association, the demand for efficient pumping solutions is surging, driven by the increasing focus on sustainability and resource conservation. The global industrial pump market is projected to grow at a CAGR of 5.8% from 2021 to 2026, emphasizing the necessity for advanced designs and technologies in water management systems.

In addition to energy efficiency, factors such as durability and ease of maintenance are critical for industrial water pumps. Data from the Global Industry Analysts indicates that an estimated 30% of energy consumption in industrial applications can be attributed to pumping systems. Therefore, selecting pumps that minimize energy usage can significantly reduce operating costs and enhance operational effectiveness.

Features like variable frequency drives and smart monitoring systems are becoming essential, allowing industries to optimize their water management processes while adhering to compliance regulations and sustainability goals. This strategic selection not only addresses immediate operational needs but also supports long-term ecological initiatives within industrial sectors.

Comparison of Performance and Efficiency Among Top Models

When evaluating industrial water pumps for efficient water management, performance and efficiency are critical metrics that directly impact operational costs and sustainability. According to a report by the International Water Management Institute, the energy consumption of water pumps can account for up to 20% of a facility's total energy usage. Therefore, selecting models with high efficiency ratings is essential for both economic and environmental reasons.

In our recent comparison of the top models, key performance indicators such as flow rate, head height, and energy consumption were analyzed. The results indicated that high-efficiency pumps not only reduce energy consumption but also provide better reliability over time. A study by the Hydraulic Institute revealed that upgrading to an efficient pump design could reduce energy costs by as much as 30%. This demonstrates the significant potential for cost savings and resource conservation in industrial settings.

Tips:

- Regularly maintain your water pumps to ensure they operate at peak efficiency; a well-maintained pump can outperform even high-rated models.

- Consider the total cost of ownership over the life of the pump, including energy, maintenance, and replacement costs, rather than just the initial purchase price.

Maintenance Tips for Longevity and Optimal Performance

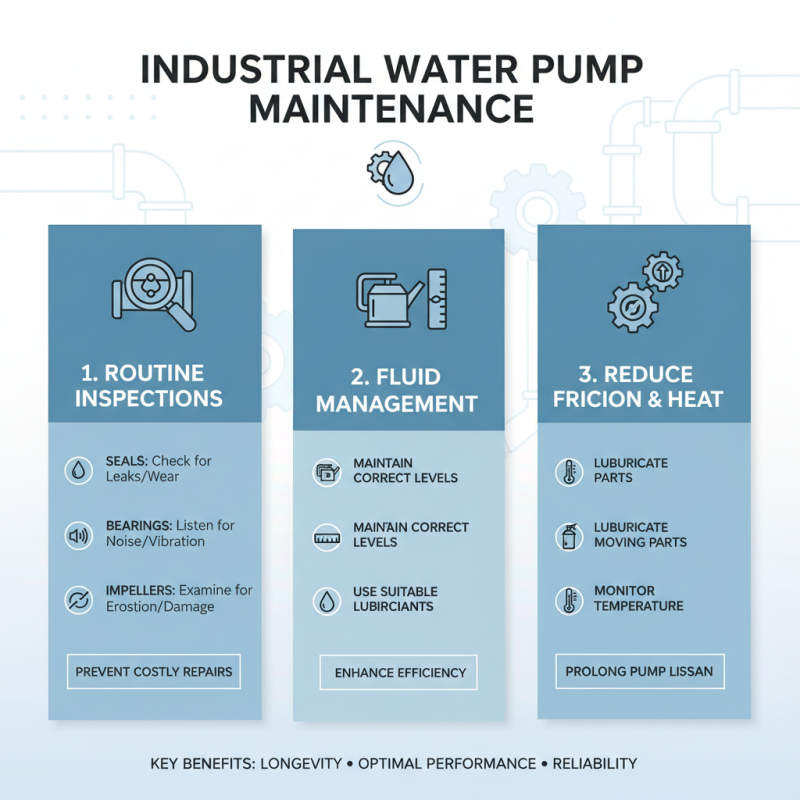

Proper maintenance of industrial water pumps is essential for ensuring their longevity and optimal performance. Routine inspections should be a priority, focusing on key components such as seals, bearings, and impellers. Particularly, checking for wear and tear can prevent small issues from escalating into costly repairs or downtime. Additionally, maintaining the correct fluid levels and using suitable lubricants can significantly enhance the efficiency of the pump, reducing friction and heat generation.

Regular cleaning is another critical maintenance step. Contaminants in the water can lead to corrosion and blockages, which can severely affect pump operation. Implementing a schedule for cleaning the intake screens and filters will help maintain a steady flow and prevent impurities from damaging internal parts. Operators should also be trained to recognize warning signs of disruption, such as unusual noise or vibrations, which could indicate underlying problems needing immediate attention. By following these maintenance tips, industrial water pumps can operate effectively for years, contributing to reliable water management solutions.

Related Posts

-

The Ultimate Guide to Understanding How Water Pumps Transform Our Daily Lives

-

2025 How to Choose the Best Water Pump for Your Home Needs

-

Exploring Market Trends for Submersible Dirty Water Pumps at the 138th China Import and Export Fair 2025

-

Understanding the Essential Role of Small Water Pumps in Everyday Life and Gardening

-

Why Water Pump Price Matters: Understanding Costs for Your Needs

-

Top 10 Dirty Water Pumps: Efficient Solutions for Heavy-Duty Water Removal in 2023